Tailored solutions for smooth operations.

11266 89 Avenue

Grande Prairie, Alberta

Troubleshooting

Lubrication Systems & Components.

Proper lubrication is crucial to the efficiency & longevity of your machinery. We offer Sourced Solutions that are as unique as your business.

Expertise and Experience: With years of experience in the lubrication industry, our team possesses the knowledge and skills to provide solutions that not only meet but exceed your expectations.

Extensive Supplier Network: Our relationships with top suppliers allow us to source high-quality and hard-to-find components quickly and efficiently. If we don't have what you need in stock, we are committed to finding it for you.

Dedicated Customer Support: Our commitment doesn't end with the delivery of your products. We offer ongoing support to ensure your lubrication systems operate effectively and continue to meet your needs over time.

If you think your operations are experiencing issues or inefficiencies (or if your Quiz score indicated that you may have issues), you may be facing one of the common problems outlined below. This page is designed to help you identify early warning signs and take the right steps to prevent costly equipment failures.

Before we begin troubleshooting your system, it is important to understand the type of lubrication system you are using. Below are the most typical systems used across industries. Each illustration includes a brief description of system operation to assist with troubleshooting.

These examples show basic system functionality but remember there are many accessories available to complement these systems, including system controllers, pressure and flow monitoring devices, gauges, pressure relief devices, rigid tubing and piping, flexible connectors, visual indicators, metering devices, strainers, filtration units, and wireless feedback systems.

Common Industrial Lubrication System Types

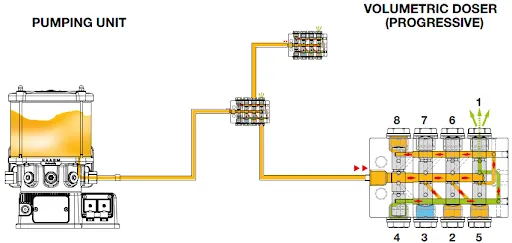

Single Line, Series Progressive System with Fixed Output Divider Valves

This system consists of an independent pumping unit that feeds volumetric distributors equipped with several outlets. Lubricant dispensing occurs through a progressive sequence, and each outlet depends on the others. If one outlet fails or becomes blocked, the entire system will stop.

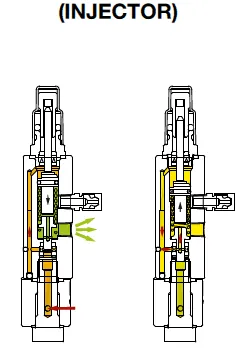

Single Line, Parallel Injector System with Adjustable Output Injectors

This system features an independent pumping unit that delivers lubricant through a single main line to independent volumetric measuring devices (injectors). Injectors operate in two phases: pressurization for lubricant delivery and depressurization for chamber reloading. Each injector can be adjusted to deliver a predetermined volume of lubricant.

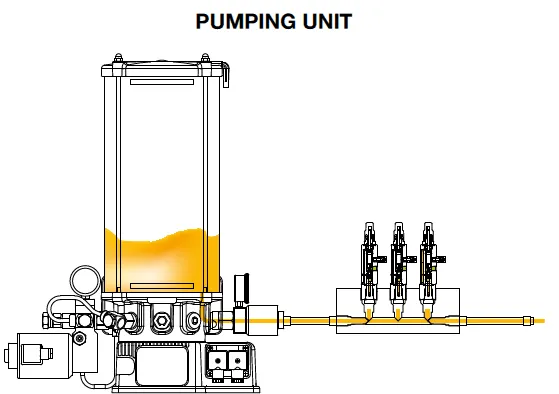

Dual Line, Parallel System with Adjustable Output Blocks

This system uses an independent pumping unit feeding two separate lines alternately. Adjustable volumetric distributors are connected to both lines to dispense predefined lubricant quantities. This design provides greater reliability for larger systems.

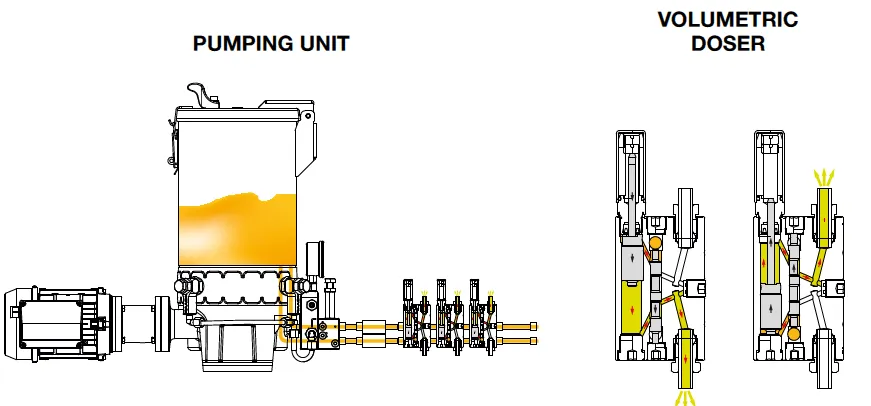

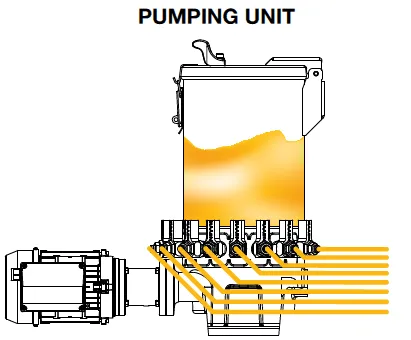

Multiple Outlet Pumping Units

This setup includes an electric central pumping station fitted radially with independent pumping elements (up to 16). A cam-driven mechanism pushes lubricant successively to different delivery points, offering continuous system operation.

Frequently Asked Questions

Why is my lubrication system not delivering grease or oil consistently?

Possible causes:

Air locks trapped in the system

Blocked lines or fittings

Bypassing injectors due to seal failure

Pump malfunction or power supply failure

Incorrect system pressure or flow rate

What to do:

Check for obstructions or leaks, verify system pressure, and inspect the pump and dispensing injectors for signs of wear. If the problem persists, contact Forward Venture Industries for a remote diagnostic or on-site inspection.

What causes my Digital No-Flow Timer (DNFT) to trigger alarms frequently?

Possible causes:

Intermittent flow caused by partial blockages

Incorrect calibration or timer setting

Worn components in the lubrication circuit

Faulty proximity switch or sensor wiring

What to do:

Review the DNFT settings and confirm proper sensor alignment. Persistent alarms may require recalibration or replacement of outdated components.

My proximity switch is not registering lubricant flow. What should I check?

Possible causes:

Sensor misalignment Debris on the sensor face

Electrical connection failure

Flow rate too low for detection threshold

What to do:

Clean the sensor face, inspect wiring connections, and ensure correct sensor placement. If issues continue, test with known flow conditions to rule out sensor failure.

How can I tell if a lubrication pump is failing?

Warning signs:

Inconsistent pressure

Unusual noise or vibration

Oil or grease leakage around the pump

Alarms or faults triggered on system monitors

What to do:

Inspect seals and fittings, check voltage and motor function, and compare current flow readings to baseline values. Pumps showing signs of wear should be serviced or replaced promptly.

What are signs of over-lubrication?

Common indicators:

Grease or oil dripping from seals or fittings

Excessive buildup around bearing housings

Shortened bearing life or overheating

What to do:

Evaluate lubrication intervals and quantity. Automated systems can help deliver precise amounts to prevent waste and protect equipment.

What causes under-lubrication?

Common causes:

Blocked or restricted lines

Incorrect pump output settings

Failed injectors or metering devices Injector fails to reload due to inadequate resting pressure venting

Missed maintenance schedules

What to do:

Check each delivery point for flow and verify injector condition. Even if system pressure is sufficient to dispense, failure to vent resting pressure can prevent injector reloading. This fault may not trigger system alarms. Confirm that system outputs meet the specific requirements of your equipment.

Are any DNFT models becoming obsolete?

Yes. The following DNFT part numbers became obsolete at the end of 2024: 000149, 000353, 000360, and 000518. Replacement models are available with improved features and compatibility.

What to do:

If you are currently using any of these models, contact our experts to review replacement options and schedule proactive upgrades during your next maintenance window.

What can I do to prevent future lubrication issues?

Best practices:

Implement automated lubrication where possible

Use proximity switches and DNFTs to monitor real-time lubricant flow

Schedule regular system inspections and replace aging components Install proper strainers and filtration systems to maintain lubricant purity

Follow manufacturer guidelines for pump settings, grease types, and maintenance intervals

Need Expert Help?

If you are experiencing any of the issues covered above or need support in optimizing your lubrication systems, Forward Venture Industries is ready to assist.

Our team offers remote diagnostics, equipment assessments, and customized solutions to help you maintain maximum uptime and operational efficiency.

Tailored solutions for

smooth operations.

11266 89 Avenue

Grande Prairie, Alberta

780-882-3198